What is Controlled demolition? The process of systematically demolishing a structure in order to achieve a certain objective. Often used for working on buildings where high control measures of safety and order are essential, controlled demolition ensures that disturbance to the surrounding structures and area is kept to a minimum.

Safety is paramount in controlled demolition , achieved by removing sections of the building in a timed process to ensure that no damage comes to the surrounding buildings, and that dust and debris can be cleared in an orderly way. All of our controlled demolition projects at M Hall Diamond Drilling are carried out using state-of-the-art machinery.

Controlled demolition can often be confused with the larger-scale demolitions involving explosives and bulldozers. Whilst this is an effective method to quickly demolish an entire building, the resulting damage to the surrounding area through large volumes of debris and dust, as well as potential safety issues, make it a far less efficient method of demolition in the long term.

Controlled demolition is not:

- Blowing up buildings with dynamite

- Using wrecking balls

- Noisy! Actually, controlled demolition enables us to work with minimal disturbance to the surrounding area.

- Brokk demolition

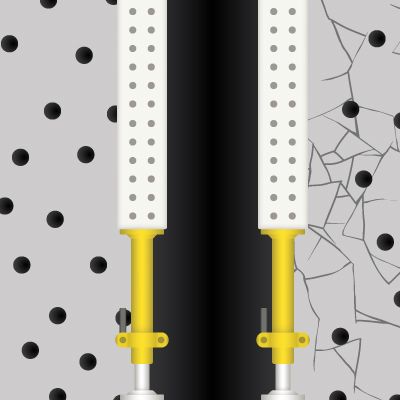

State-of-the-art Brokk demolition machines allow our team to carry out skilled demolition procedures in the safest, and most environmentally friendly way. Using three-phase electric power, Brokk equipment means there are no fumes from gas-fuelled power. Brokk machinery allows for a robotic demolition, minimising the risk to our team and everyone else in the surrounding area.

- Drilling and bursting

This method is used in controlled demolition by creating holes in the concrete structure to create weaknesses, with a hydraulic burster head to crush the concrete. This method is much quieter than when using Brokk equipment, and is ideally used in ‘live’ buildings or residential areas, although it will take significantly longer. Our structural engineers will often advise you use this method when you can’t use vibrations.

When you contact us regarding a controlled demolition project, we’ll need some information to ensure we can provide the safest, service for your requirements. Our qualified team will do a full site survey of the building, and will need to know what type of building it is, whether other areas of the building will still be occupied while the demolition of another part is taking place, timescales, and the setup of your site.

Our useful Get a Price page allows you to fill out all the information we’ll require to understand your diamond drilling needs. Simply contact us today on 0800 0986 190 for further information or to discuss your requirements.